Danobat and Soraluce present their latest generation solutions for industrial manufacturing at the EMO trade fair

-

Both companies, part of the industrial group Danobatgroup, will have a prominent presence at the fair, which will be held between 16 and 21 September in Hanover.

-

Under the slogan "Together beyond challenges", the manufacturer Danobat will showcase its high-value technological developments in the field of precision and digitization.

-

Meanwhile, Soraluce will exhibit its manufacturing capabilities of large gantry machines, multi-function solutions and top-level machining engineering services.

The Basque manufacturers of machine tools and advanced production systems Danobat and Soraluce, part of the industrial group Danobatgroup, present their state-of-the-art solutions to meet the challenges of the industry at the next edition of the EMO trade fair, which will be held in Hanover from 16 to 21 September.

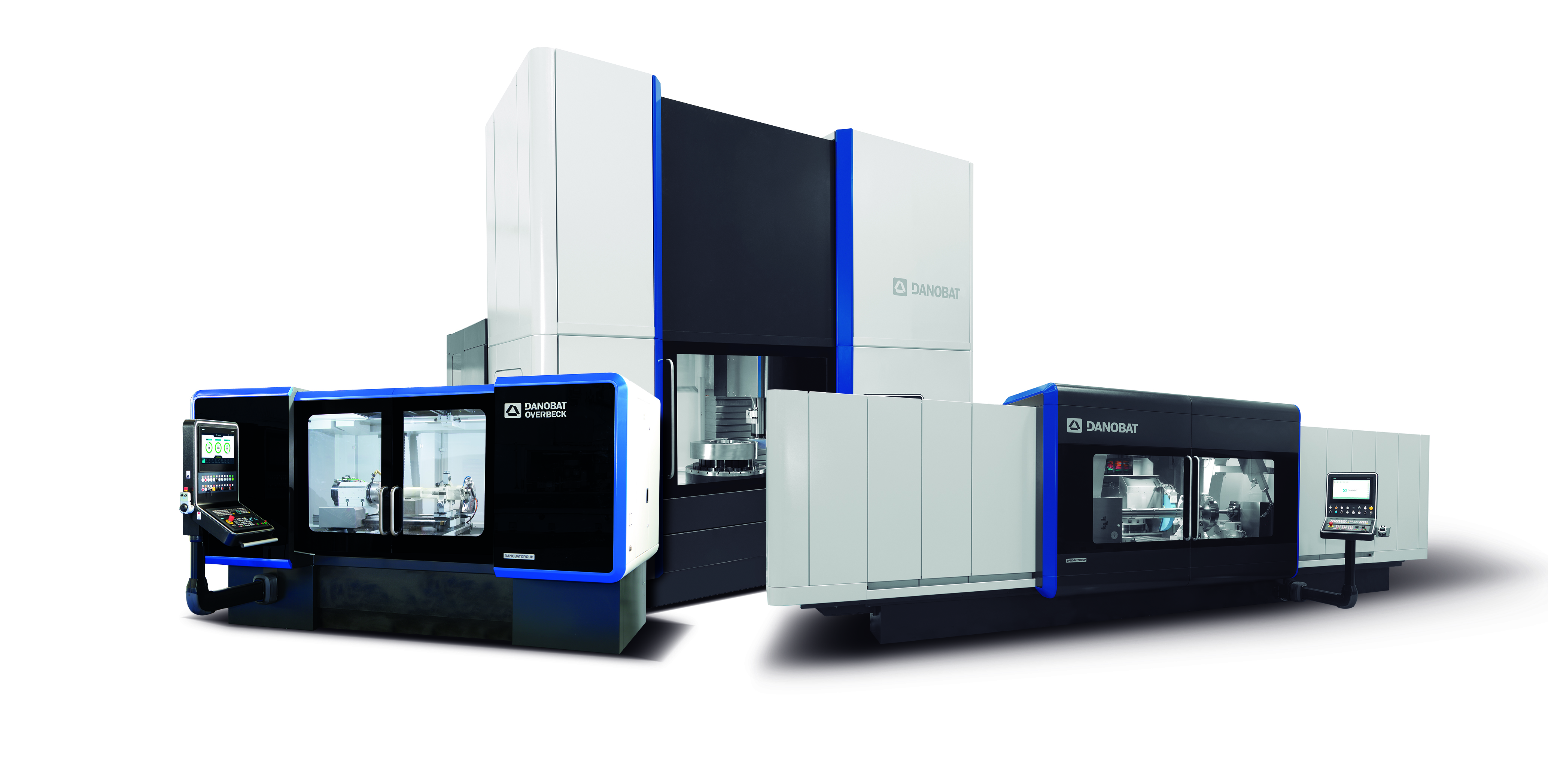

Under the slogan "Together beyond challenges", Danobat will present at the event a total of eight machines of high technological value, three of them fully automated, that have been conceived for performing high-precision grinding and turning processes. The firm will also provide information on the advanced services it offers, as well as on the advancements made on digital technologies.

The Elgoibar company, which will have an exhibition space of 700 square metres (stand D-45, Hall 11), will present a fully automated system for grinding the closure of the injector of car engines and an external grinding machine model LG-1000 with an integrated gantry.

It will also exhibit the ESTARTA-650 centerless grinder and the HG-72 grinder, redesigned to manufacture 1500 mm long parts for Siemens electric motors.

Danobat will also have the VG-800 vertical grinder on show, which combines external and internal grinding and measuring operations, and a high-precision lathe for hard turning, which suits the requirements of manufacturers who frequently need to modify the type of part they produce.

The manufacturer will also exhibit the IRD-400 and ILD-400 grinders, developed by its German subsidiary Danobat-Overbeck.

In addition to these solutions, conceived to increase the competitiveness of the industrial sector and fully adapted to the machining needs of its customers, Danobat will also unveil its offer of advanced services and its advancements in industrial digitalisation through the "MyDanobat" platform, a new portal that provides greater control and knowledge of machinery.

"Our capacity for the development of tools and digital technologies has enabled us to generate a set of services specifically geared towards boosting the competitiveness of our clients by responding to the challenges of the industry of the future", assures the CEO of Danobat, Xabier Alzaga.

A customer-geared service

Soraluce in turn, is using the event to exhibit its portfolio of machining solutions, as well as the services they offer in its own exhibition space of 860 square meters, the largest area located in the middle of the hall dedicated to milling (stand B38, hall 13).

The company, a firm believer in innovation and cutting-edge technologies, will exhibit three machines, seven technologies and offer eight live demonstrations within its new concept #MadeForYOU. This idea includes milling machines, large gantry machines, multifunctional solutions, automated lines and advanced services.

"The result of #MadeForYOU is one of the most complete and advanced ranges of products and services on the market. This offer focuses on the smart machine concept with which Soraluce demonstrates its ability to respond to common machining problems, in addition to providing geometrically accurate results that go beyond market standards. It also includes machining engineering services, carried out by a team of specialists who offer solutions to boost productivity, efficiency and profitability of our customers," says Rafael Idígoras, CEO of Soraluce.

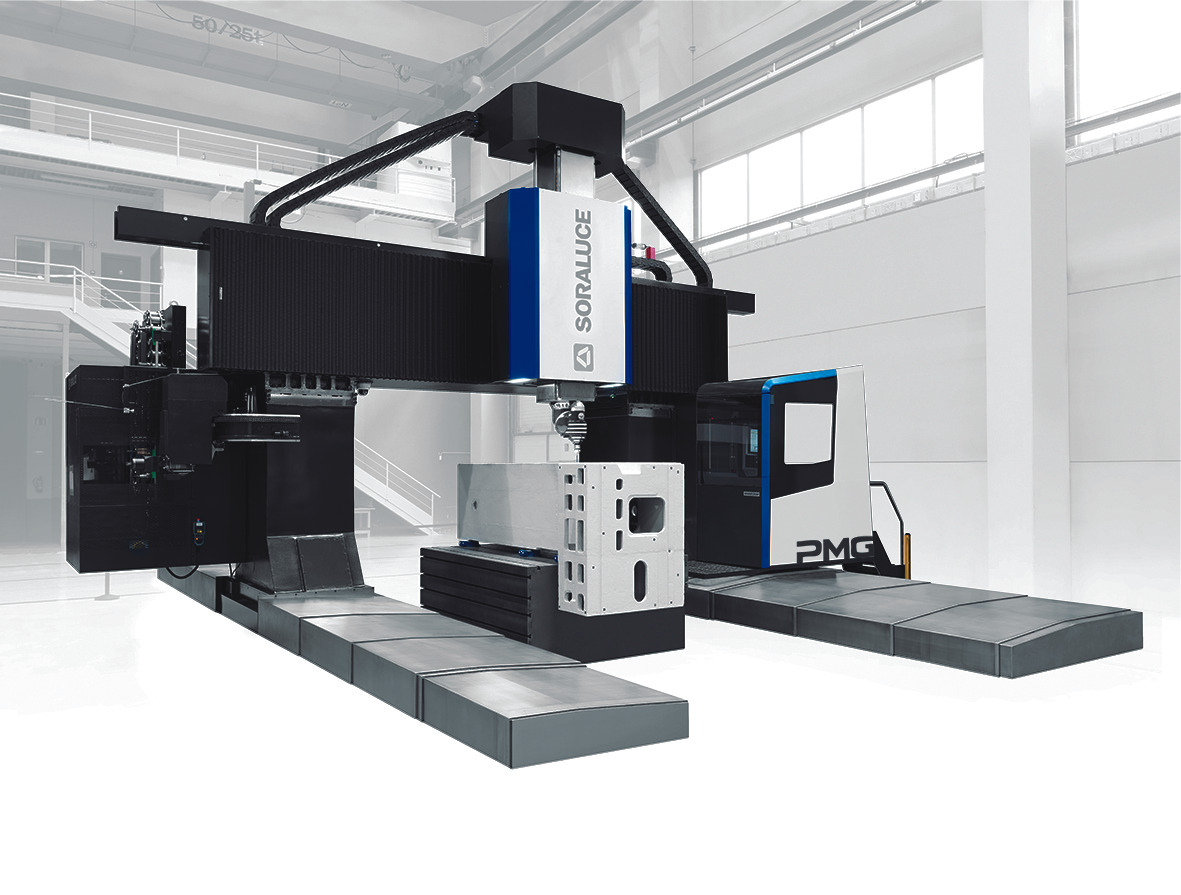

Specifically, the Bergara firm will bring to EMO a new Soraluce TR-M multifunction centre that integrates milling, turning and grinding operations on the same machine. The manufacturer will also be exhibiting a Soraluce FP 8000 travelling column milling-boring machine, equipped with the new 2-axis continuous head for 5-axis machining, and the new Soraluce PGM 14000 gantry milling machine, a high-precision, high-productivity solution for large components.

Soraluce PMG gantry milling machine

Soraluce PMG gantry milling machine

In addition, the company will exhibit at the EMO the patented DAS+® and DWS systems, aimed at cancelling chatter during machining. These are intelligent damping solutions that maximise stock removal capacity.

Another of the technologies presented will be the VSET system, which allows time savings of up to 70% in the alignment of parts.

The EMO will bring together more than 2,200 exhibitors on an area of 180,000 square metres at the Hanover exhibition centre.

About Danobat

Danobat dvelops advanced machine tools and production systems for applications aimed at high-tech sectors and customers who demand high technical requirements.

The company is strongly internationalised and has production plants in Spain, UK and Germany, besides centres of excellence in the latter countries as well as in Italy, USA and China.

Danobat is part of Danobatgroup, an industrial group that employs 1,300 people and invests 8% of its turnover in R&D&I projects.

About Soraluce

World leader in milling, boring and turning technology, Soraluce has made innovative and pioneering contributions to manufacturing processes, which have become industry standards since their inception 55 years ago.

With more than 3,000 machines sold worldwide, almost half of them on the tough German market, Soraluce is part of Danobatgroup, the machine tool division of the Mondragon Corporation, one of Europe´s largest business groups.

About Danobatgroup

With 65 years of experience in the field of technologies applied to industrial manufacturing, Danobatgroup has a staff of over 1,300 highly qualified people. The group is an international benchmark in the sector of machine tools and technologies applied to industrial manufacturing.