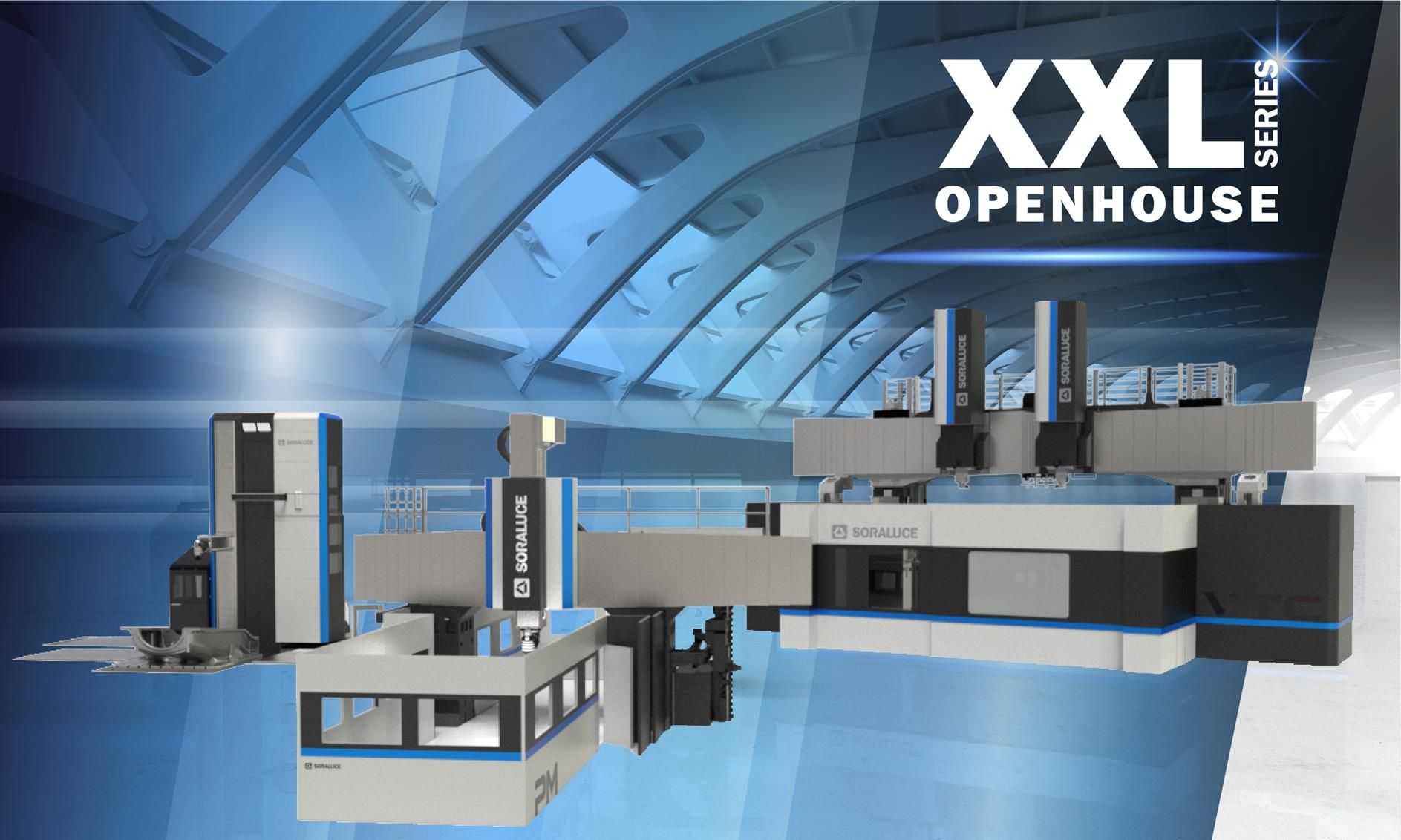

Heavy duty capacity, precision and versatility at a large scale during SORALUCE XXL Series Open House

-

XXL Series machines can be customised to meet specific requirements

-

SORALUCE multitasking solutions enhance productivity

-

Technology corner with the last SORALUCE developments

-

Live demonstrations

The SORALUCE XXL Series Open House will be held from 6 to 9 March at our Bergara facility in Spain, where we’ll present our latest innovative products, technologies and solutions to meet the requirements of large-size and heavy-duty milling, boring and turning.

Wide range of machines

SORALUCE offers a wide range of heavy-duty milling, boring and vertical turning machines, multitasking solutions and automated systems which offer precision and versatility when machining large-sized components.

Productivity through multitasking

SORALUCE will also be showcasing multitasking technology applied to heavy-duty components.

Multitasking machines enhance the profitability of machining technically-complex parts. A single machine offers multiple cutting processes, including turning, milling, boring, drilling and tapping. This enables efficient production of large scale workpieces of different shapes, with precision. The number of set-ups required is reduced and cycle times and potential errors are minimised. Great precision can also be achieved, with tolerances to two decimal places on large-sized workpieces, even those weighing hundreds of tonnes.

Live demos

Innovation is at the forefront of everything SORALUCE does. As a result, many of the technologies that drive the machine tool sector have been pioneered by SORALUCE, such as the patented DAS systems (Dynamics Active Stabiliser), Modular Quill and RAM Balance Systems.

For further information: https://www.soraluce.com/en/soraluce-xxl-series-openhouse